At Precision Industrial our intent is to improve the air quality at your facility and to provide a safer working environment for you and your team. We have dealer relationships with many different air filtration equipment manufacturers, so you can rest assured that we will select the best piece of equipment for your application. We will not attempt to make your application fit our piece of equipment; we will make our piece of equipment fit your application. This is one of the reasons that make Precision Industrial the best choice to address your air quality needs. Some types of dust collectors that we sell and install are listed below.

Horizontal Cartridge Dust Collector

ACT Dust Collectors are quality-built in the United States to stand up to your rugged manufacturing environment. From small to large jobs, the dust systems of ACT Dust Collectors are designed to handle many applications, including welding smoke, grinding, cutting tables, blast applications, sanding, thermal spray, coating, bulk powders, and many more dust collecting processes.

With millions of CFM going through operating ACT Dust Collectors every day worldwide, we have the solution to every application. Custom designed and built systems are common, and our engineering team can help find the dust collection system that’s right for you. Dirty air from the dust source enters the A.C.T. dust collector at the top of the main housing. There are inlets on the roof and optional inlets on the front for the most efficient connection. As air enters the dust collector, dust accumulates on the outside of the filters as air is drawn through the high-efficiency media. The air flowing down through the system greatly assists the fallout of dust into the hopper where it is discharged. When the pulse clean system activates and accumulated dust is released from the cartridges, the air flowing downward through the collector assists dust fallout again. This avoids dust from getting re-entrained and accumulating on the filter again.

Features

- Venturi assisted pulse filter cleaning

- Control box with digital timer in NEMA 4

- ACTion lock quick release filter doors

- Stainless steel filter door components

- Front and top inlets

- Premium goyen valve

- Multicoat paint finish

- UL certified panels

- Primed interior

Recommended for

- Weld smoke and fumes

- Fine particulate dust in food, chemical, metal working, grain, plastics, pharmaceuticals industries

- Air volumes of 400 CFM to 128,000 CFM

Pulse Jet Baghouse Dust Collectors

Scientific Dust Collectors manufactures a full line of Baghouse Dust Collectors to meet the needs of your specific operation. For over 35 years, SDC has provided customers with unmatched cleaning performance due to our superior cleaning system that employs a patented supersonic nozzle to clean the filters more effectively than any of our competitors.

Baghouse Dust Collectors are ideally suited to capture dusts that are larger or more difficult to clean. Dusts that are high temperature or hygroscopic are better suited for collection in baghouse dust collectors. In addition, larger dust sizes (greater than 50 microns) and higher grain loadings (over 5 grains per cubic foot) are ideal for baghouse units. Dusts that have a tendency to form films that solidify should be handled in fabric baghouse collectors. If hydrocarbons are present in the airstream, the same problems may occur. For these types of applications, baghouses are recommended because the dust cake may require flexing before the cake will burst. Some examples of dust that are collected using fabric filter baghouses are: flyash, coal, cement, lime, fiberglass, paper, plastic, sawdust, and other stringy or irregular shaped dusts.

Features

- Patented cleaning nozzle technology

- High side baffled inlet with drop out area

- Wide bag spacing: 2.5″-3″ between bags

- Solid state timer pre wired in NEMA 4

- Zinc oxide primer on the interior and exterior with an external finish of industrial enamel

- 12 gauge steel housing reinforced to withstand +/- 20 IWC

- Standard structure designed to withstand 115 MPH winds and zone 3 seismic loads

Recommended for

- Larger more difficult to clean dust with higher grain loadings

- High temperature and hygroscopic dust

- Dust that have a tendency to form films

- Flyash, coal, cement, lime, fiberglass, paper, plastic, sawdust, and other stringy or irregular shaped dusts

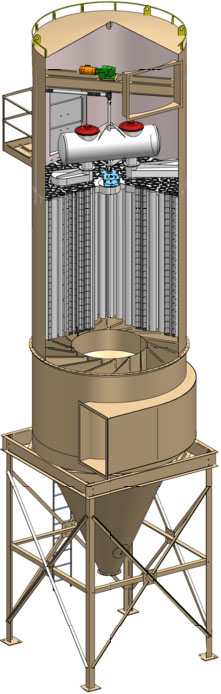

Cyclonic Baghouse Dust Collector

HONEYVILLE MPC CYCLONIC FILTERS are recommended for light to medium dust load applications utilizing cyclone separation and bag filtration as the final stage. This design uses a 110° involute inlet with an inner cyclone baffle and vortex breakers to insure minimal air swirl in the bag chamber with the primary material separation taking place in the 67° cone section. The involute inlet allows for better material separation in the filter by providing an extended transition as the dust laden air enters the cyclone. By increasing the material separation in the cyclone section, the dust load on the bags is significantly decreased allowing for better air flow and extended bag life.

THE MPC BAGHOUSE FILTER will effectively filter all types of wood waste as well as grain, feed, flour, cement products and plastics. The filter utilizes high volume, medium pressure cleaning of the bags. The cleaning is mechanically timed so that the air pulse occurs when the nozzles are centered over the bags.

THE MPC FILTER OPERATES AS FOLLOWS: Dust laden air enters the involute inlet directly above the cone section. Large particles enter the cone section, separate and exit out the bottom while smaller particles flow upward into the bag’s chamber and are retained on the exterior of the filter bag. The clean air flows upward through the bag and exits via the open top of the bags into the clean air plenum. This air may be vented outside or returned back inside a building.

Features

- Bag Cleaning: Medium pressure back flush cleaning of bags

- Cone: 67° standard cone section with bolt-on inspection cover

- Inlet: Low pressure 110° involute inlet section with inner cone baffle and vortex breakers

- Optional high entry inlet

- Bags: 4.6″ dia. 16 oz. polyester bags with mirror finish

- Cages: 4.5″ dia. galvanized wire cages

- Bag Removal: No-tool top bag and cage removal

- Construction: Welded and bolted construction using hot rolled carbon steel

- Rupture type explosion relief panels

- Finish: The interior and exterior are prime coated followed by a silicone alkyd industrial enamel paint on the exterior

Recommended for

- Medium to heavy dust load applications utilizing cyclone separation and bag filtration

- Grain, feed, flour, minerals, cement products, plastics, paper, and wood industries

Indoor Baghouse

The Nederman S-Series is an enclosureless, silent and simple to set up dust collector suitable for wood and sawdust applications (furniture, cabinetry, windows, doors, flooring, particle board, MDF, building materials, marine, and sawmills) and for general dust collection where feasible.

It is designed for indoor installation compliant with NFPA combustible dust regulations. They are available in three sizes: the S-500, S-750 and S-1000 ranging from 1,500 – 5,000 CFM, providing a cost-effective filtration solution for small and medium-sized workshops.

Features

- High performance Superbags reduces bag replacement needs down to 3-5 years

- Energy efficient fans utilize an impeller design that is 20% more efficient than common radial blade fans

- Silent operation with high performance fans run only 10-15 dB(A) over normal conversation sound level

- Provide safety and reliability for your workplace and manufactured in compliance with the latest NFPA standards

- Unique collapsible design with pre-installed fan and SuperBags minimize installation time and effort with 3 step easy and quick installation.

Recommended for

- High speed routing

- Sawing and cutting

- Single cell manufacturing

- After filters

Mechanical Shaker Baghouse Dust Collector

The Honeyville Shaker Filter (“SF”) Series is ideal for small shops where you have the option to shut down the system periodically to shake the bags. It is available in 8 sizes with a recommended capacity range from 1,000 CFM to 6,000 CFM. This unit can be installed inside or outside your shop

The SF Series can be designed for use as an after filter for venting air from a primary cyclone. Some light dust applications allow the SF Series to be connected directly to a fan outlet serving as a primary filter.

Features

-

Construction: All galvanized, bolted steel construction for years of service. 14 and 16 Ga. panels, 12 Ga. cell plate.

-

Assembly Arrangements: Open Bag Area Units if installed indoors or Totally Enclosed Units for outdoor or indoor installations

-

Bag Shaker Options: Manual Shaker or Motorized Shaker (required on totally enclosed units)

-

Bags: 5″ dia. 10.5 oz polyester seamless knit bags

-

Hopper: Low profile hopper, sloped hopper w/ steel barrels, or sloped hopper w/ plastic collection bags

-

Return Air: Optional return air manifold for outdoor installations

Recommended for

- Cyclone after filters

- Light dust applications

- Grain, feed, flour, plastics, paper, and wood industries

- Indoor or outdoor locations

Cyclone Dust Collector

Honeyville Metal has 21 sizes of standard (MH) cyclones available for a large range of applications. The MH model cyclones are frequently used for applications in the milling, woodworking, feed processing, seed cleaning, and other industrial dust collecting operations.

For applications involving abrasive materials such as wet sawdust, sand, plastic, cement dust, foundry dust, or other metal dusts, the MH cyclones can be supplied heavy duty or extra heavy duty in hot rolled (“HR”) carbon steel, galvanized steel, stainless steel, and abrasion resistant (“AR”) steel for extended wear.

Features

- MATERIAL: All welded HR steel with butt seam construction. Three gauge thickness classifications available: Standard Duty, Heavy Duty, and Extra Heavy Duty. Optional Materials: AR Steel, G90 Galvanized Steel, and Stainless Steel.

- VENT: Each cyclone has a flanged vent for use with an Adjustable Vent Cap or a Return Air Manifold.

- ROOF: All sizes over 30″ diameter have a 15 degree conical roof for greater vent tube stability.

- SAFETY RING: On MH36 and larger sizes, a safety ring mounted at roof edge is standard

- EXTERIOR SURFACE: The exterior of cyclones made with HR or AR steel are finished with a base primer coat followed by a Industrial Alkyd Enamel paint.

- Cone access door: 14″ diameter, bolt-on panel, flush with the inside surface. Standard on all cyclones 36″ dia. and larger. Optional 20″ dia. door.

Recommended for

- Medium to heavy dust load applications with larger particulate utilizing cyclone separation

- Material separator to be installed before a baghouse or cartridge collector

- For applications involving abrasive materials such as wet sawdust, sand, plastic, cement dust, foundry dust, or other metal dusts

- For applications involving dry dust such as milling, woodworking, feed processing, seed cleaning, and other industrial dust collecting operations