When Everris company reached out to Precision Industrial Services, Inc. about there dust problem in their manufacturing facility, they had an existing dust collection system in place. This dust collection system consisted of a cyclone material separator that was about 1/3 of the size of what they actually needed. After completing system analysis we came up with a plan to design and install a new dust collection system for them that would be large enough to handle all the processes in their manufacturing facility.

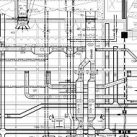

Precision Industrial supplied an explosion isolation damper to be installed in the main ductwork to prevent any possible explosions from propagating from the cyclone separator back inside the plant. The cyclone was also equipped with an explosion vent to relieve pressure in the case of an explosion.After the cyclone separator and explosion isolation damper were installed, the new ductwork system had to be installed. The new ducting was much larger making it capable to handle all of the dust collection pick up points required by the equipment.

There was one challenge that we faced while designing the ductwork system. This plant had a station where they would dump super sacks full of material into large bins with forklifts. We had to design a hood system that could capture the dust generated during this process. We engineered a hood for each bin that would supply enough airHow to capture the majority of the dust generated. Each hood was equipped with an automatic blast gate that would open only when the operator was using that particular bin. This reduced the amount of air by only pulling dust through the one hood that was being used. This generated a huge savings in both the initial investment of a dust collection system and the long-term cost of electricity.